Shark Air CNC Cutting Machine

HAVE A QUESTION ABOUT SHARK AIR CNC PLASMA CUTTERS?

Ask a Question- Welded Steel Construction

- Dual Side Rack & Pinion Drive System

- Bosch Rexroth Linear ways on ALL Axes

- Bosch Rexroth Bearing Blocks on ALL Axes

- NEMA 34 Stepper Motors

- Low Backlash Planetary Gear Boxes

- Z-Axis Automatic Plasma Torch Lifter

- Ohmic Sensing & Collision Sensors

- Supports up to 2” Plate

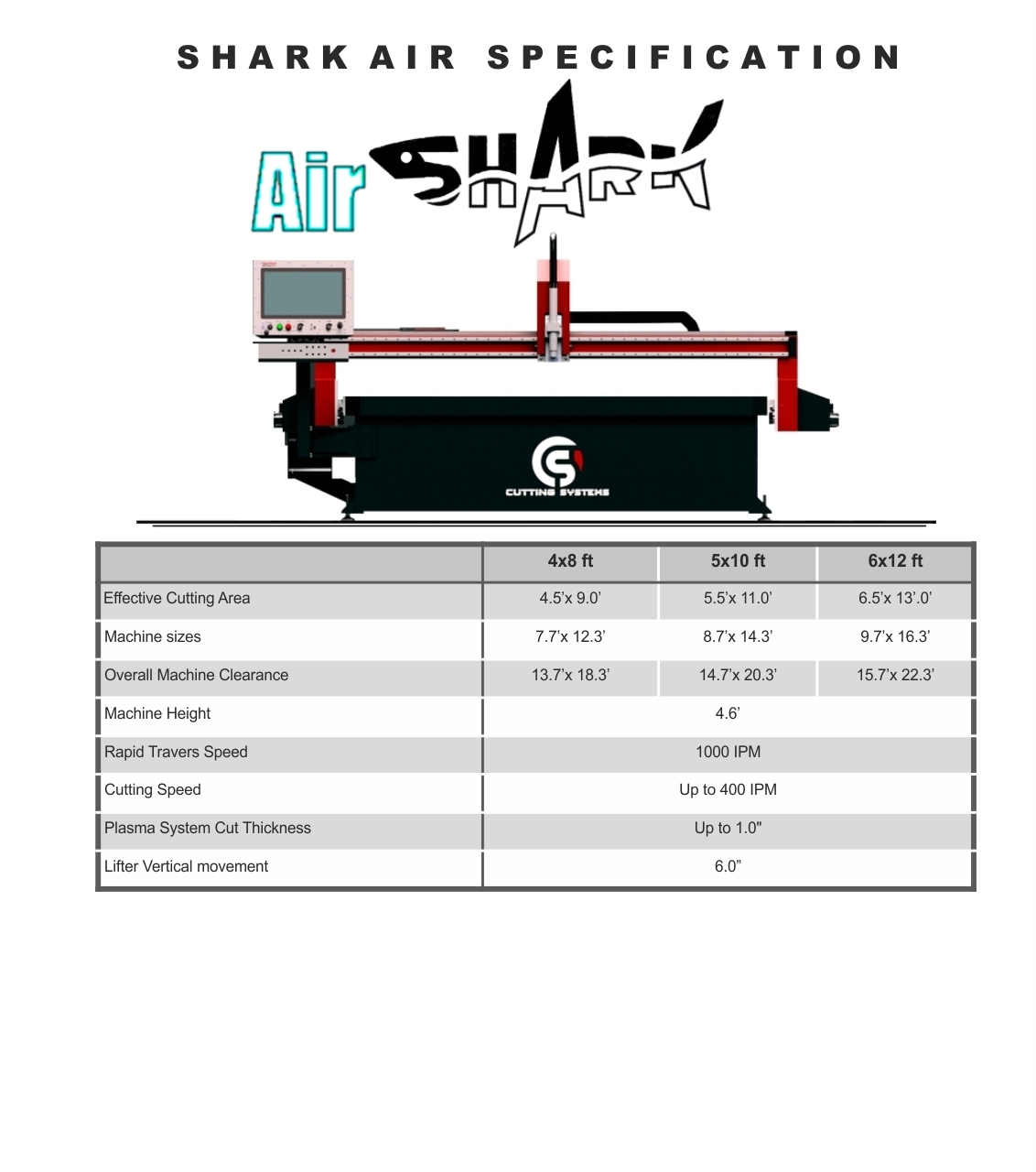

- Rapid Traverse Speeds up to 1000 IPM

- Water or Downdraft Tables Available

- Standard 110 / 220v Single Phase Power

- Industrial Grade Igus Power Track Cable Management

- Proximity Sensors for homing, auto squaring, and safety limits

- FlashCut CNC Controller and Drive System

- Table Sizes Available: 4X8 / 5X10 / 6X12

- Shark Air CNC Plasma Cutting Machine is an industrial-grade air plasma cutting system.

- Industrial grade precision and durability at an air plasma price point.

- The perfect solution for light to medium industrial applications.

- Unitized construction means easy setup and installation.

- FlashCut CAD/CAM software will get the most out of every sheet of steel.

Plasma Power Supplies Available:

- Hypertherm Powermax 30 Air Plasma

- Hypertherm Powermax 30 XP Air Plasma

- Hypertherm Powermax 45 Air Plasma

- Hypertherm Powermax 65 Air Plasma

- Hypertherm Powermax 85 Air Plasma

- Hypertherm Powermax 105 Air Plasma

- Hypertherm Powermax 125 Air Plasma

- Hypertherm Maxpro 200 Conventional Plasma

- Thermal Dynamics A40 Air Plasma

- Thermal Dynamics A60 Air Plasma

- Thermal Dynamics A80 Air Plasma

- Thermal Dynamics A120 Air Plasma

- Lincoln Electric Tomahawk 375 Air Plasma

- Lincoln Electric Tomahawk 625 Air Plasma

- Lincoln Electric Tomahawk 1000 Air Plasma

- Lincoln Electric Tomahawk 1500 Air Plasma

Additional Options:

- Water Table or Downdraft Options Available

- Standard Table Sizes: 4X8 / 5X10 / 6X12

Shark Air CNC Plasma Cutting Machine

Shark Air CNC Plasma Cutting Machine