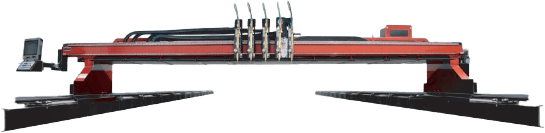

Custom CNC Cutting Machines & Engineered Solutions

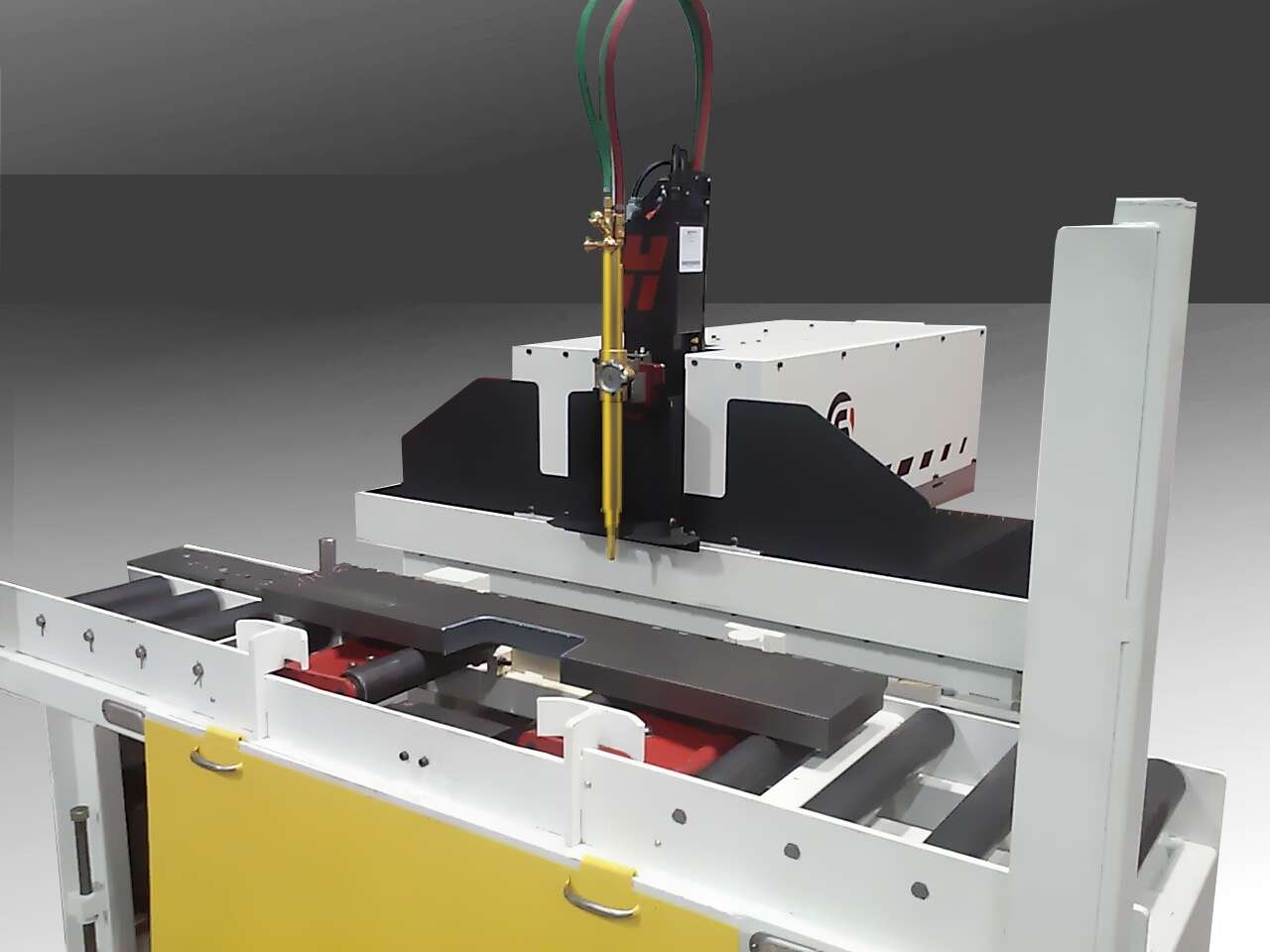

At Cutting Systems, we specialize in designing and manufacturing fully customized industrial CNC machines. Whether you need plasma or oxyfuel cutting machines, we work with you to create a solution that maximizes productivity and efficiency. Our steel-cutting machines are built to improve workflow, delivering faster results than other systems.

We offer various customizable controls and features to create the perfect fit for your industry. Our CNC machines come equipped with Hypertherm PC-based CNC controls, heavy-duty welded steel frames, precision-machined gantry beams, and Yaskawa drive systems with EtherCAT technology.

We guarantee excellent performance and long-term durability with AC servo motors and low-backlash planetary gearboxes. Cutting Systems can engineer a custom CNC cutting machine to meet your requirements, ensuring the most efficient solution for your steel-cutting operations.

Tailoring CNC Cutting Solutions

Cutting Systems is a top manufacturer of highly customized industrial CNC machines that can enhance productivity and efficiency in any industry. Our primary focus is on air, plasma, and oxyfuel cutting, and we tailor each machine to meet specific client needs. Optional features include Hypertherm controls, Yaskawa drive systems, and high-performance servo motors. Cutting Systems offers durable and precision-engineered machines to help clients improve their workflow and complete the job faster. Contact us today to gain access to the most efficient steel-cutting systems tailored to you.