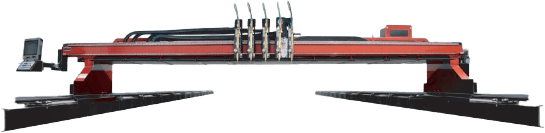

Plasma & CNC Oxy-Fuel Cutting Machines

Cutting Systems offers a premium lineup of plasma and oxyfuel cutting machines tailored to meet the diverse needs of industries such as steel fabrication, mining, automotive, and heavy equipment manufacturing. Each machine—Kodiak, Cobra, Raptor, SaberCut, and Shark—is engineered for precision, durability, and advanced automation, ensuring top-tier performance in industrial CNC cutting applications.

Built for heavy-duty performance, the Kodiak combines a solid steel bridge with the advanced Hypertherm CNC motion control system for precise plasma and oxyfuel cutting. Its compatibility with Hypertherm XPR and HPR systems ensures consistent cuts across various materials, and its water and downdraft tables enhance workplace safety.

The Cobra is a powerful solution for bevel cutting, ideal for creating weld-ready parts without secondary processing. Its robust build, coupled with precise Hypertherm plasma systems, simplifies the production of complex cuts, maximizing productivity.

The Raptor is built for large-scale production and offers exceptional cutting power and flexibility. Its industrial-grade construction and advanced automation make it suitable for demanding applications in steel service centers and mining.

The SaberCut excels in oxyfuel cutting, delivering superior precision for heavy industrial applications. Its customizable configurations and advanced torch systems make it a reliable choice for large-scale cutting projects.

CNC Unitized Plasma Cutting Machine: Shark

Key Features

The Shark offers both high-definition plasma cutting and air plasma options designed for light to medium industrial applications. Its compact design, affordability, and reliable performance make it an excellent choice for manufacturers and fabricators.

Custom Engineered Solutions

Cutting Systems is proud to be a leading manufacturer of top-rated, fully customizable industrial CNC machines. Whether you’re looking for air, plasma, or oxyfuel CNC machines, our steel-cutting machinery is made to deliver maximum productivity for increased workflow in less time than other systems. Our steel-cutting machines come standard with a variety of customized controls perfectly suited to match your industry needs.